Rotary Lobe Pumps

ROTARY LOBE PUMPS

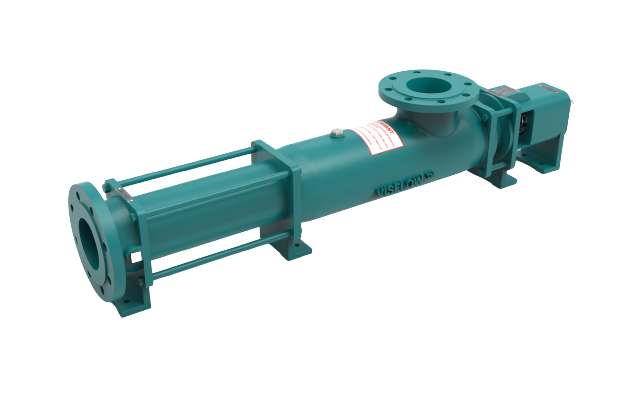

VISFLOW HELICAL PUMPS

Rotary Lobe pumps are Positive-Displacement type Pumps that use two or more lobes rotating around Parallel Shafts in the pump’s body to move liquids. They are widely used for both Hygienic Applications & Industrial Applications. Our Lobe Pumps require less maintenance and is made using Quality Tested material using latest machineries to ensure efficient running of pump.

Team

Our Members

PRINCIPLE

ROTARY LOBE PUMPS

VISFLOW HELICAL PUMPS

A positive displacement pump operates by trapping a fixed amount of fluid from an intake pipe and then displacing that trapped volume into a discharge pipe. Lobe pumps utilize intermeshing 4-wing helical lobes mounted on parallel shafts. The shafts are rotated by gears with a maintenance friendly design (no complicated timing gears to worry about). As the lobes un-mesh on the intake side, they create a cavity with an expanding volume. Your sludge or slurry flows into the cavity and is trapped by the lobes as they rotate. The sludge or slurry then travels around the interior of the casing in the void between the lobes and the housing segments. The pumped material does not pass between the lobes. As the lobes begin to mesh on the discharge side, the lobes force the sludge or slurry through the outlet port under pressure. The capacity of material being pumped can be changed by varying speed of the pump.

HYGIENIC & INDUSTRIAL

Applications of Rotary Lobe pumps

Material Option

VISFLOW HELICAL PUMPS

MATERIAL OF CONSTRUCTION

RECOMMENDED SPARES

DRIVE OPTIONS

CUSTOMIZED OPTIONS

Construction

1. Pump Chamber: AISI Stainless Steel 316

2. Tri Lobe Rotor: AISI Stainless Steel 316

3. Top Cover: AISI Stainless Steel 316

Shaft: AISI Stainless Steel 316

4. Seal: Mechanical Seal

5. Gear: EN-24

6. Casing: Cast Iron

7. Back Cover: Cast Iron

8. Bearing Spacer: Cast Iron

9. Bearing: SKF

Drive Options

1. Close Coupled Drive : Electric Motor, Gear Motor 2. Direct Drive : Electric Motor, Gear Motor 3. Belt Pulley Drive : Belt & Pulley Drive 4. Petrol Engine, Diesel Engine, Hydraulics, Pnenumatics.

Recommended Spares

1. Rotor

2. Shaft

3. Gear

4. Seal

5. O-Ring

6. Gasket

7. Oil Seal

8. Bearing

9. Cover

10. Chamber

Drive Options

1. Close Coupled Drive : Electric Motor, Gear Motor 2. Direct Drive : Electric Motor, Gear Motor 3. Belt Pulley Drive : Belt & Pulley Drive 4. Petrol Engine, Diesel Engine, Hydraulics, Pnenumatics.

Drive Options

1. Gear Motor Drive

2. Electric Motor Drive

3. Belt Pulley Drive

4. Petrol Engine

5. Hydraulic

6. Pneumatic

7. Diesel Engine.

Drive Options

1. Close Coupled Drive : Electric Motor, Gear Motor 2. Direct Drive : Electric Motor, Gear Motor 3. Belt Pulley Drive : Belt & Pulley Drive 4. Petrol Engine, Diesel Engine, Hydraulics, Pnenumatics.

Customized Options

1. AISI Stainless Steel 304 Rotors & Shafts

2. Two Leaves Rotor, Tri Leaves Rotor & Five Leaves Rotor

3. Butterfly Rotor & Spiral Rotor

Trolley Mounted Base Plate with Handle

4. VFD with Control Panel

5. AISI Stainless Steel 304 / 316 Sheet Base Plate

6. Flange type Inlet-Outlet connections with companion flanges.

Drive Options

1. Close Coupled Drive : Electric Motor, Gear Motor 2. Direct Drive : Electric Motor, Gear Motor 3. Belt Pulley Drive : Belt & Pulley Drive 4. Petrol Engine, Diesel Engine, Hydraulics, Pnenumatics.

2000

Start JourneySubham Industries Inception

Sister Concern firm

2002

LaunchLaunched Pin - Bust Joint

Progressive Cavity Pump (Bare Shaft)

2004

LaunchLaunched Pin Bust Joint

Progressive Cavity Pump (Close Couple)

2007

Visflow Helical PumpsVisflow Helical Pumps Inception

New Brand name with modern facility

2009

LaunchHeavy duty Pump Launch

Heavy Duty Cardon Joint Progressive Cavity Pumps (Bare Shaft)

2011

LaunchHeavy duty Pump Launch

Heavy Duty Cardon Joint Progressive Cavity Pumps (Close Couple)

2013

Moving ForwardMoving forward to manufacturing Facility

Moved to our own modern manufacturing facility in Coimbatore.

2015

ISOReciving ISO

Received ISO 9001 [URS] in the year 2015 for Progressive Cavity Pump Manufacturing , Developed Retrofit Spares for Progressive pumps & Gear pumps

2016

DevelopmentDeveloped Retrofit Spares

Developed Retrofit Spares for progressive cavity pumps of various domestic brands

2018

DevelopmentDeveloped Retrofit Spares

Developed Retrofit Spares for progressive cavity pumps of various domestic brands

2019

DevelopmentDeveloped Progressive Cavity Pumps

Developed Progressive Cavity Pumps Delivery flow Upto 350 M/Hrs and Developed Progressive Cavity Pumps Handling Pressure Upto 48 Bar

2021

DevelopmentDeveloped Gear Joint Pumps

Developed Gear Joint Progressive Cavity Pumps

ROTARY LOBE PUMPS

TECHNICAL FEATURES

- Capacity Up-to 350 LPM

- Discharge Pressure Up-to 7 Bar

- Operating Temperature Up-to 250°C

- Suitable for Low to High viscosities

- Gentle Liquid Handling

- Dry Running Capability

- Low Noise Level

- Easy Maintenance

- Ensures Smooth Flow

- High Efficiency

- Designed for Hygienic & Industrial Applications

ROTARY LOBE PUMPS

DESIGN FEATURES

- AISI Stainless Steel 316 Tri Lobe Rotor

- AISI Stainless Steel 316 Cover

- Splined Shaft

- Oil Level Viewing Point

- Over Dimensioned Front Bearings

- Robust Reliable System Rear Bearings

- Helical Gears

- Front Loaded Mechanical Seals

- Interchangeable Shafts & Rotor

- Easy Cleaning with CIP Process

ROTARY LOBE PUMPS

PERFORMANCE

PUMP MODEL

STANDARD PORT SIZE

FLOW at 100 RPM [LPM]

PRESSURE

MAXIMUM SPEED

PUMP MODEL

- VLB-100S

- VLB-100L

- VLB-150S

- VLB-150L

- VLB-200S

- VLB-200L

- VLB-250S

- VLB-250L

- VLB-300S

- VLB-300L

- VLB-400S

- VLB-400L

STANDARD PORT SIZE

- 1’’

- 1’’

- 1 ½’’

- 1 ½’’

- 2’’

- 2’’

- 2 ½’’

- 2 ½’’

- 3’’

- 3’’

- 4’’

- 4’’

FLOW at 100 RPM [LPM]

- 5

- 8

- 12

- 18

- 26

- 38

- 55

- 79

- 116

- 175

- 261

- 354

PRESSURE

- 7

- 7

- 7

- 7

- 7

- 7

- 7

- 7

- 7

- 7

- 7

- 7

MAXIMUM SPEED

- 1000

- 1000

- 1000

- 1000

- 1000

- 1000

- 1000

- 1000

- 600

- 600

- 500

- 500