Customized Progressive Cavity Pumps

Team

Our Members

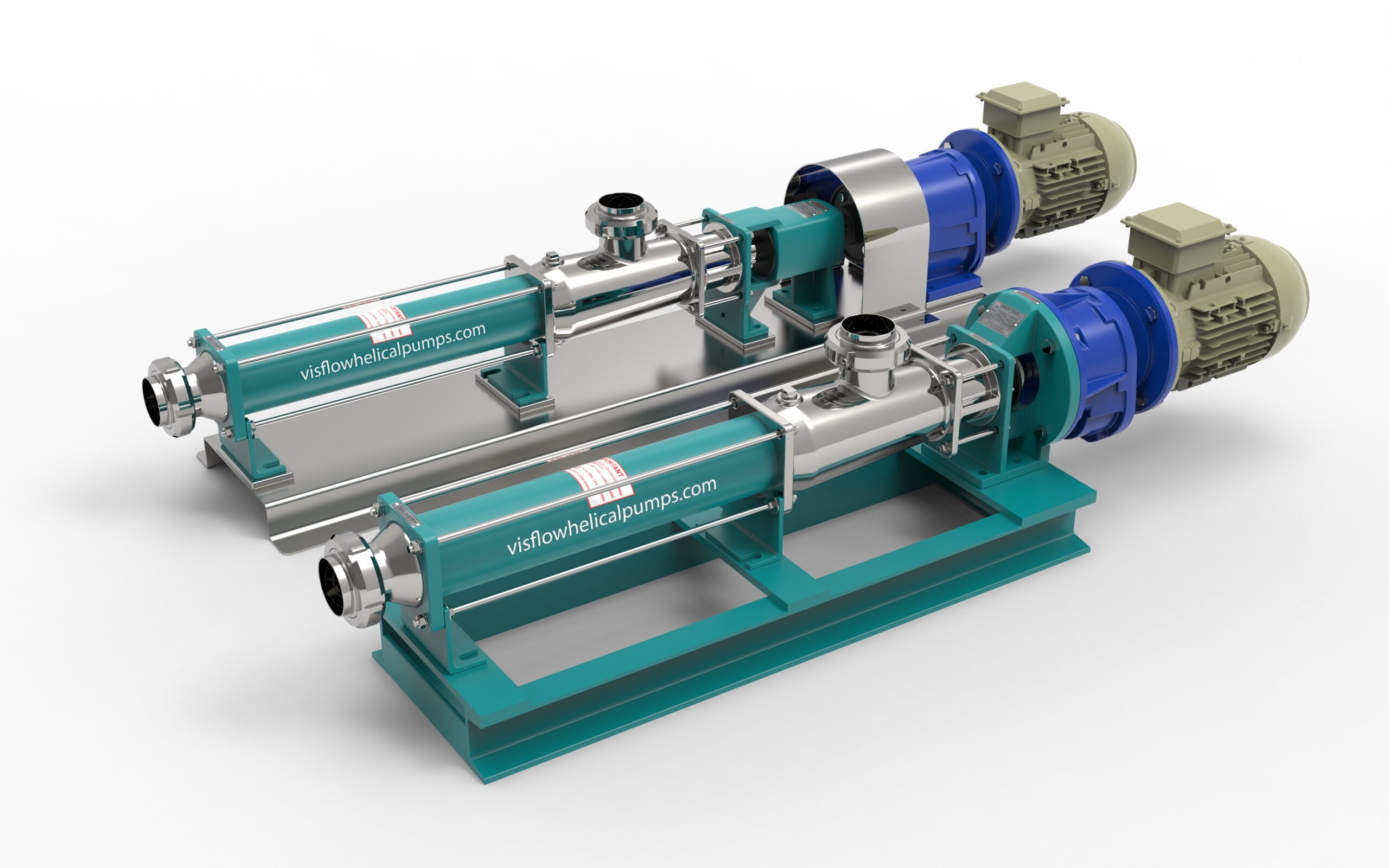

PROGRESSIVE CAVITY RANGE OF PUMPS

CUSTOMIZED DEVELOPMENTS

Box Title

2. Customized Rotor & Stator according to requirement.

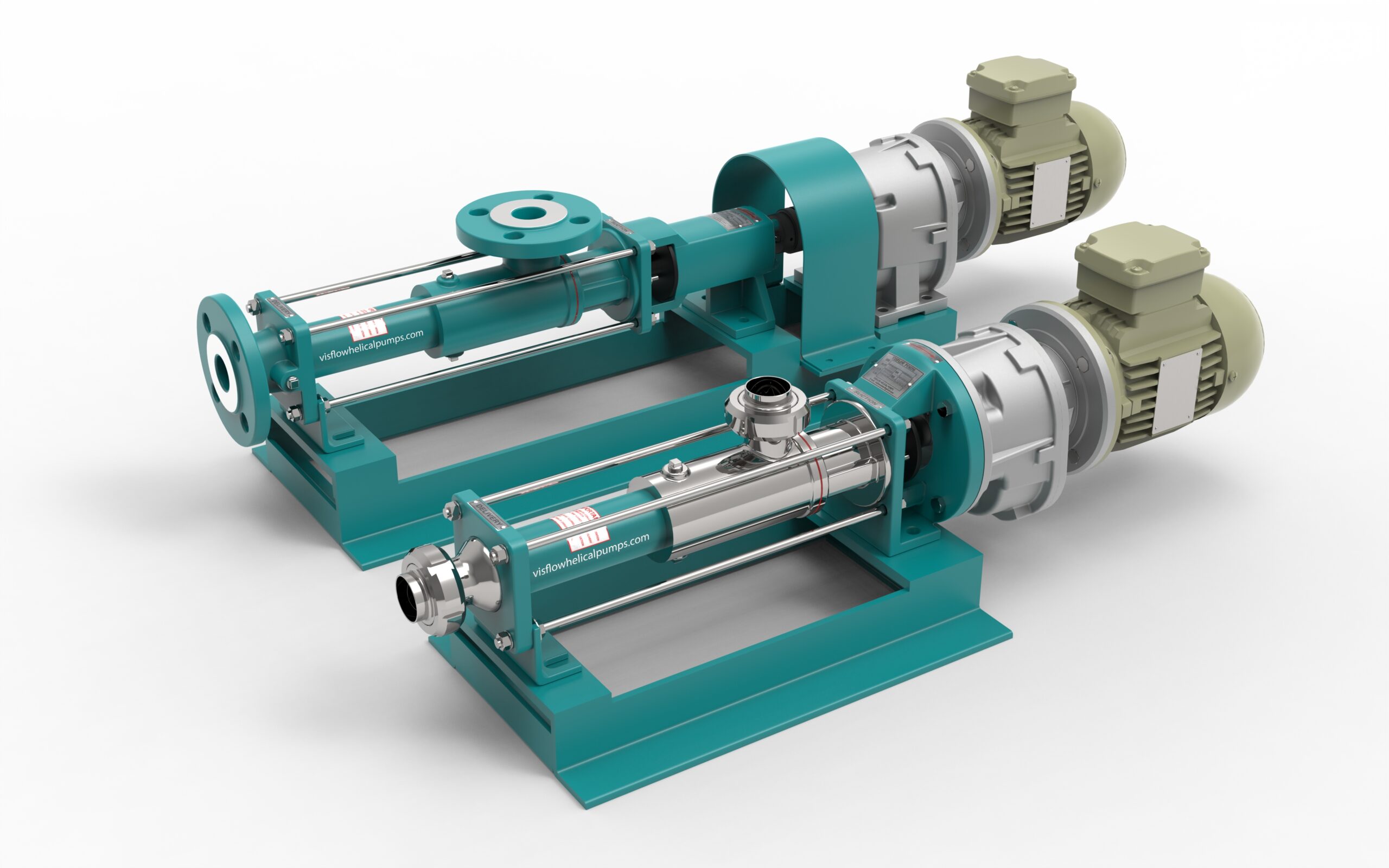

3. Customized Housing Parts for Pump according to requirement.

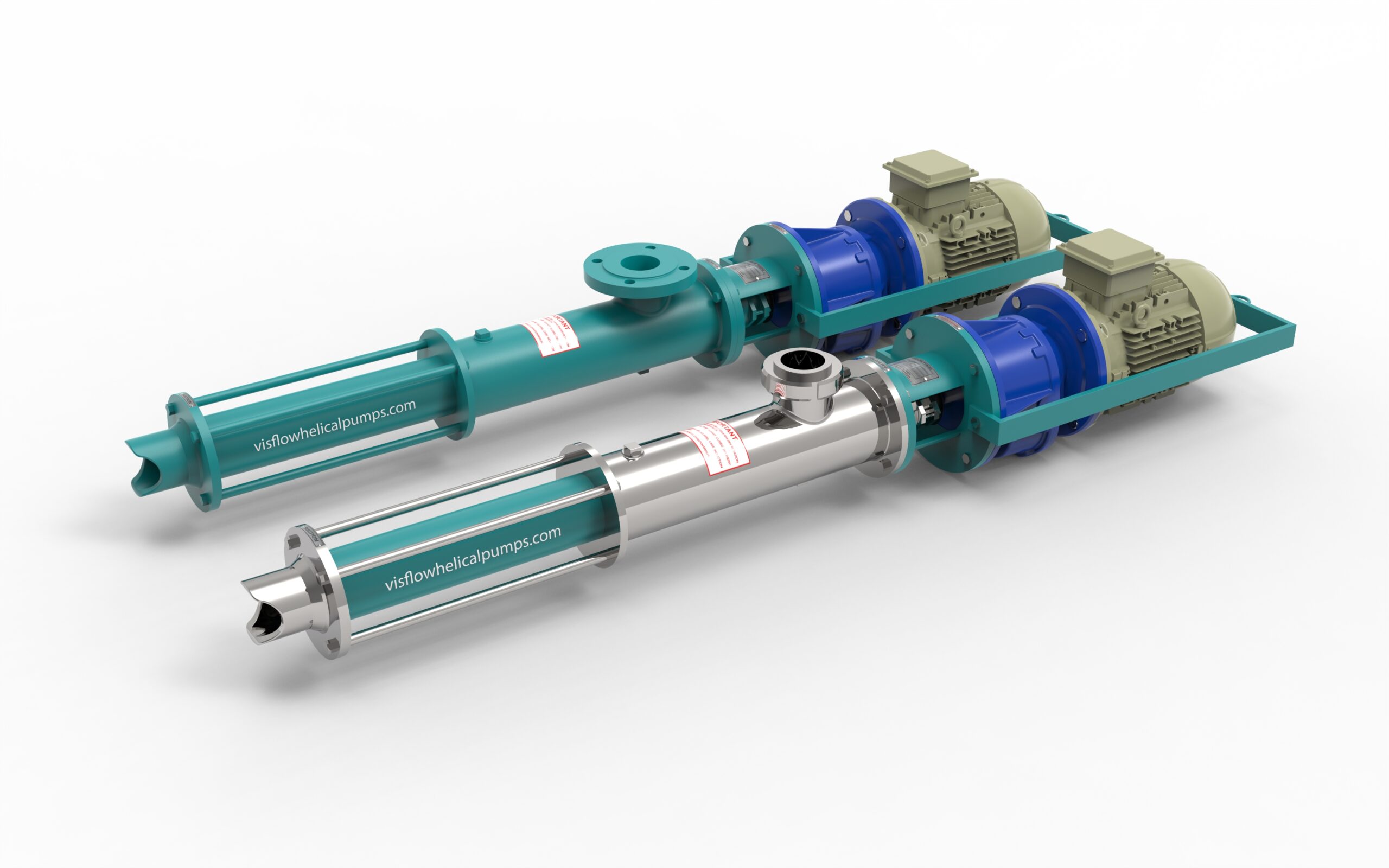

4. Customized Drive Arrangements for Pump according to requirement.

5. Customized Base Plate for Pump according to requirement.

Customized Progressive Cavity Pump according to requirement.

1. Close Coupled Drive :

Electric Motor, Gear Motor

2. Direct Drive :

Electric Motor, Gear Motor

3. Belt Pulley Drive :

Belt & Pulley Drive

4. Petrol Engine, Diesel Engine, Hydraulics, Pnenumatics.

Drive Options

1. Close Coupled Drive : Electric Motor, Gear Motor 2. Direct Drive : Electric Motor, Gear Motor 3. Belt Pulley Drive : Belt & Pulley Drive 4. Petrol Engine, Diesel Engine, Hydraulics, Pnenumatics.

Customized Rotor & Stator according to requirement.

1. Common Base Plate for Pump

2. Pulley & Belt for Pump

3. Coupling for Pump

4. Guard for Pulley or Coupling

5. Fasteners

6. Companion Flanges.

Drive Options

1. Close Coupled Drive : Electric Motor, Gear Motor 2. Direct Drive : Electric Motor, Gear Motor 3. Belt Pulley Drive : Belt & Pulley Drive 4. Petrol Engine, Diesel Engine, Hydraulics, Pnenumatics.

Customized Housing Parts for Pump according to requirement.

1. Electric Motor

2. Gear Box

3. Gear Motor

4. Variable Frequency Drive

5. Control Panel

6. Dry Running Protection Device

7. Pressure Switch

8. Pressure, Vacuum & Differential Gauges

9. Relief Valve

10. Strainers.

Drive Options

1. Close Coupled Drive : Electric Motor, Gear Motor 2. Direct Drive : Electric Motor, Gear Motor 3. Belt Pulley Drive : Belt & Pulley Drive 4. Petrol Engine, Diesel Engine, Hydraulics, Pnenumatics.

Customized Drive Arrangements for Pump according to requirement.

1. Common Base Plate for Pump

2. Pulley & Belt for Pump

3. Coupling for Pump

4. Guard for Pulley or Coupling

5. Fasteners

6. Companion Flanges.

Drive Options

1. Close Coupled Drive : Electric Motor, Gear Motor 2. Direct Drive : Electric Motor, Gear Motor 3. Belt Pulley Drive : Belt & Pulley Drive 4. Petrol Engine, Diesel Engine, Hydraulics, Pnenumatics.

Customized Base Plate for Pump according to requirement.

1. Common Base Plate for Pump

2. Pulley & Belt for Pump

3. Coupling for Pump

4. Guard for Pulley or Coupling

5. Fasteners

6. Companion Flanges.

Drive Options

1. Close Coupled Drive : Electric Motor, Gear Motor 2. Direct Drive : Electric Motor, Gear Motor 3. Belt Pulley Drive : Belt & Pulley Drive 4. Petrol Engine, Diesel Engine, Hydraulics, Pnenumatics.

2000

Start JourneySubham Industries Inception

Sister Concern firm

2002

LaunchLaunched Pin - Bust Joint

Progressive Cavity Pump (Bare Shaft)

2004

LaunchLaunched Pin Bust Joint

Progressive Cavity Pump (Close Couple)

2007

Visflow Helical PumpsVisflow Helical Pumps Inception

New Brand name with modern facility

2009

LaunchHeavy duty Pump Launch

Heavy Duty Cardon Joint Progressive Cavity Pumps (Bare Shaft)

2011

LaunchHeavy duty Pump Launch

Heavy Duty Cardon Joint Progressive Cavity Pumps (Close Couple)

2013

Moving ForwardMoving forward to manufacturing Facility

Moved to our own modern manufacturing facility in Coimbatore.

2015

ISOReciving ISO

Received ISO 9001 [URS] in the year 2015 for Progressive Cavity Pump Manufacturing , Developed Retrofit Spares for Progressive pumps & Gear pumps

2016

DevelopmentDeveloped Retrofit Spares

Developed Retrofit Spares for progressive cavity pumps of various domestic brands

2018

DevelopmentDeveloped Retrofit Spares

Developed Retrofit Spares for progressive cavity pumps of various domestic brands

2019

DevelopmentDeveloped Progressive Cavity Pumps

Developed Progressive Cavity Pumps Delivery flow Upto 350 M/Hrs and Developed Progressive Cavity Pumps Handling Pressure Upto 48 Bar

2021

DevelopmentDeveloped Gear Joint Pumps

Developed Gear Joint Progressive Cavity Pumps